Concrete Batching Plant

Concrete Batching Plant

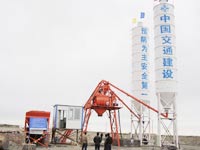

Mini Concrete Batching Plant

- Model: HZS commercial series

- Productivity: 40—240m3/h

- Mixer: JS series concrete mixer

- Batching Machine: PLD series batching machine

- Control System: Integration Industry Computer Control or PLC+PC Control System

- Standard: GB/T 10171-2005

(※ Click this button to inquiry)

(※ Click this button to inquiry)

Next:Back To List

- Concrete Batching Plant

- Commercial Concrete Batching Plant

- Ready Mix Concrete Plant

- Project Concrete Batching Plant

- Belt Conveyor Concrete Batching Plant

- Concrete Mixer Plant

- Precast Concrete Plant

- Mini Concrete Batching Plant

- Concrete Mixing Plant

- HZS180 Concrete Mixing Plant

- HZS120 Concrete Mixing Plant

- HZS90 Concrete Mixing Plant

- HZS60 Concrete Mixing Plant

- HZS50 Concrete Mixing Plant

- HZS35 Concrete Mixing Plant

- HZS25 Concrete Mixing Plant

- HZS75 Concrete Mixing Plant

- JS Concrete Mixer

- JS1000 Concrete Mixer

- JS750 Concrete Mixer

- JS500 Concrete Mixer

- JS1500 Concrete Mixer

- JS2000 Concrete Mixer

- JS3000 Concrete Mixer

- SICOMA Concrete Machinery

- SICOMA Concrete Mixer MAO Standard Series

- SICOMA Concrete Mixer MEO Economical Series

- SICOMA Concrete Mixer MSO Mini Series

- SICOMA Planetary Concrete Mixer

- SICOMA Cement Screw Conveyor

- SICOMA Butterfly Valve

- SICOMA Dust Collector

Introduction:

We, Zhengzhou Great Wall Machinery Manufacture Co., Ltd, our mini concrete batching plant an economical practical concrete mixing plant for small scale project and users who require lower than 50m3/h capacity. It is with features of vast application, small size land needed, low investment, easy to remove etc.

Part of Configurations Features:

Mixing System:

1) Our JS Series mixer is with 9 technical patents, it is with strong mixing power, high mixing evenness and high productivity.

2) The mixing blade and liner is made by high wearing-resistance chromium-manganese alloy.

3) The hydraulic discharging door angle is adjustable.

4) The shaft end sealing system is by multi-sealing structure effectively prevents leakage and guarantees the continuous long running of whole mixing system.

5) Motors and speed reducers are of China Famous Brand Product.

The Batching and Feeding System:

1) The PLD series batching machine is by accumulated weighing system with high stability and efficiency.

2) The batching aggregates can be 2-4 types as per the unique needs of customers.

3) The sensors for the weighing system are of China Famous Brand with assured high weighing accuracy and stability.

4) The feeding system is of hopper type, low land requirement, low investment.

Weighing System:

1) Apart the standard water, cement weighing system, the additive weighing system is optional.

2) The sensors for the weighing system are of China Famous Brand with assured high weighing accuracy and stability.

3) The pneumatic butterfly valve is full aluminum for high performance and forever non-corrosion.

The Centralized Control System:

We use full auto SIMENS PLC+PC centralized control model. Buyer can also use PLC semi-auto control system or manual control system to hugely save cost, the control room, air conditioning system is also optional.

Application:

GREAT WALLmini concrete batching plant can be widely used in samll construction projects like buildings, roads, bridges etc.

OUR TWO PROMISES:

1) We are the only CHINA WELL KNOWN TRADEMARK enterprise in Xingyang Henan, all our equipments is strictly designed and manufactured as per China National Standard Requirement, and high guaranteed on terms of advanced technology, deep technology maturity and promised output capacity.

2) We provide turn-key project solution with all needed equipment and parts (cables and wires are all included). We solemnly promise that, apart from the power and materials, the buyers needs no extra investment for any other parts to run our plant.

Parameters Table:

| HZS25 | HZS35 | HZS50 | ||

| Theory Productivity(m3/h) | 25 | 35 | 50 | |

| Standard Discharging Height(m) | 3.8 | 3.8 | 4.2 | |

| Mix Cycle Time(s) | 72 | 72 | 60 | |

| Total Power(KW) | 52 | 75 | 105 | |

| Mixer Model | JS500 | JS750 | JS1000A | |

| Batching Machine Model | PLD800 | PLD1200 | PLD1600A | |

| Feeding Method | Hopper | Hopper | Hopper | |

| Weighing Accuracy | Aggregate | ≤2 | ≤2 | ≤2 |

| Cement and Ash Coal | ≤1 | ≤1 | ≤1 | |

| Water | ≤1 | ≤1 | ≤1 | |

| Additive | ≤1 | ≤1 | ≤1 | |

| MOQ | 1 set | 1 set | 1 set | |

| Delivery Time | 7days | 7days | 10days | |

| Delivery Port | Qingdao or Tianjin | |||

Introduction:

We, Zhengzhou Great Wall Machinery Manufacture Co., Ltd, our mini concrete batching plant an economical practical concrete mixing plant for small scale project and users who require lower than 50m3/h capacity. It is with features of vast application, small size land needed, low investment, easy to remove etc.

Part of Configurations Features:

Mixing System:

1) Our JS Series mixer is with 9 technical patents, it is with strong mixing power, high mixing evenness and high productivity.

2) The mixing blade and liner is made by high wearing-resistance chromium-manganese alloy.

3) The hydraulic discharging door angle is adjustable.

4) The shaft end sealing system is by multi-sealing structure effectively prevents leakage and guarantees the continuous long running of whole mixing system.

5) Motors and speed reducers are of China Famous Brand Product.

The Batching and Feeding System:

1) The PLD series batching machine is by accumulated weighing system with high stability and efficiency.

2) The batching aggregates can be 2-4 types as per the unique needs of customers.

3) The sensors for the weighing system are of China Famous Brand with assured high weighing accuracy and stability.

4) The feeding system is of hopper type, low land requirement, low investment.

Weighing System:

1) Apart the standard water, cement weighing system, the additive weighing system is optional.

2) The sensors for the weighing system are of China Famous Brand with assured high weighing accuracy and stability.

3) The pneumatic butterfly valve is full aluminum for high performance and forever non-corrosion.

The Centralized Control System:

We use full auto SIMENS PLC+PC centralized control model. Buyer can also use PLC semi-auto control system or manual control system to hugely save cost, the control room, air conditioning system is also optional.

Application:

GREAT WALLmini concrete batching plant can be widely used in samll construction projects like buildings, roads, bridges etc.

OUR TWO PROMISES:

1) We are the only CHINA WELL KNOWN TRADEMARK enterprise in Xingyang Henan, all our equipments is strictly designed and manufactured as per China National Standard Requirement, and high guaranteed on terms of advanced technology, deep technology maturity and promised output capacity.

2) We provide turn-key project solution with all needed equipment and parts (cables and wires are all included). We solemnly promise that, apart from the power and materials, the buyers needs no extra investment for any other parts to run our plant.

Parameters Table:

| HZS25 | HZS35 | HZS50 | ||

| Theory Productivity(m3/h) | 25 | 35 | 50 | |

| Standard Discharging Height(m) | 3.8 | 3.8 | 4.2 | |

| Mix Cycle Time(s) | 72 | 72 | 60 | |

| Total Power(KW) | 52 | 75 | 105 | |

| Mixer Model | JS500 | JS750 | JS1000A | |

| Batching Machine Model | PLD800 | PLD1200 | PLD1600A | |

| Feeding Method | Hopper | Hopper | Hopper | |

| Weighing Accuracy | Aggregate | ≤2 | ≤2 | ≤2 |

| Cement and Ash Coal | ≤1 | ≤1 | ≤1 | |

| Water | ≤1 | ≤1 | ≤1 | |

| Additive | ≤1 | ≤1 | ≤1 | |

| MOQ | 1 set | 1 set | 1 set | |

| Delivery Time | 7days | 7days | 10days | |

| Delivery Port | Qingdao or Tianjin | |||

0086-371-63250997

0086-371-63250997